Common Wear Marks Wall Of Shame (aka- You BONE HEAD!)

They we’re brand new when they left….

(New at one time!-Yes)

(Packaged correctly -Yes)

(Delivered correctly-Yes).

Very Often we Take Pics of the The New stuff minutes before it ships and post on web when we need product pics.

Now the rest is on you!…

(aka- You)

Common BONE-HEAD MARKS! See page below WALL-OF-SHAME! All winners!

Sent in for Rehab- Received like this You Dirty Dog! -Just unwrapped-

(so you ride in Rocks and “My Cousin Vinnie” Red Mud all day…)

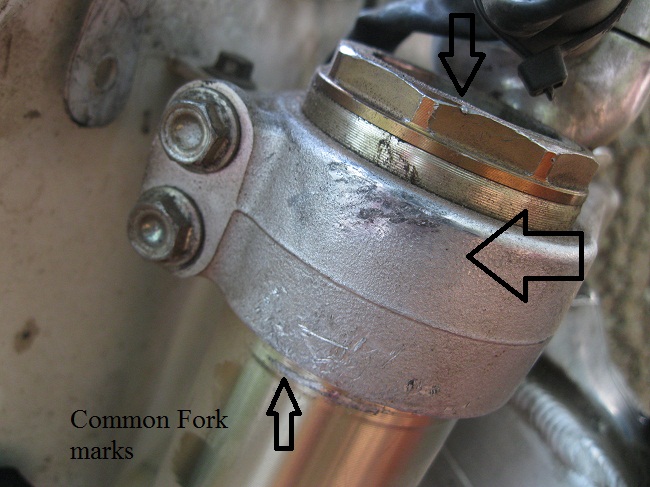

Many Common Wear Marks are Found On Forks and Shocks! (See More Pics Below…)

We take as many pics as Possible and Add Them To “The-Wall-Of Shame” when we see a good one!

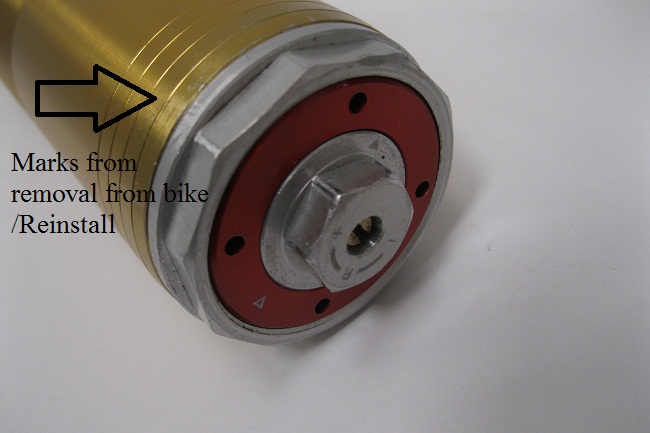

Usually a customer tears the forks off and quickly, tosses them in a pick-up truck rolling around with other junk or in a flimsy box to ship without proper packing!

Pretty much just using any forks or shocks makes common marks on them! (see more below…)

They only start looking at them more carefully when they get them back,

Thinking any mark or scratch was not there before which is not correct! Then “Then they post a negative review” to show their ignorance. BOTTOM LINE, WE ENJOY OUR EARNED SUCCESS and BEST EFFORTS TO PROVIDE ALL WE CAN, AS BEST WE CAN.

Does FED-EX “GROUND” really mean “All-OVER-THE-GROUND” for your route?

Most shipping issues are when a dealer, parts kid or customer sends a box In-Bound without proper packaging and their carelessness.

Make boxes easy to handle and well packaged and you’ll have much better results!

2)

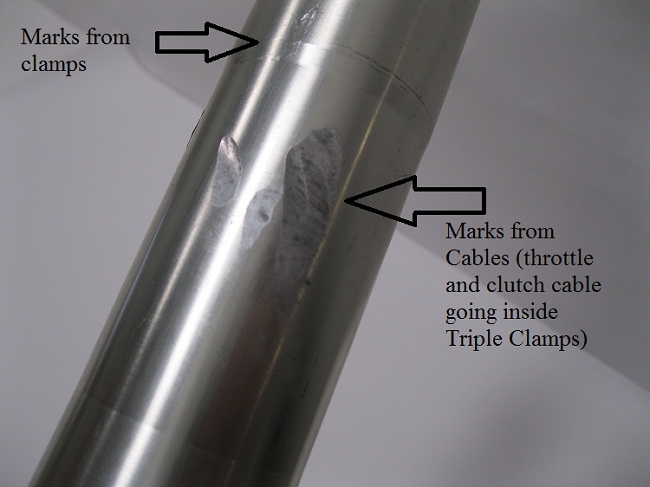

“The Cable Wear” (a classic) cables routing inside your triple clamps touch when bars turn back and forth.

3)

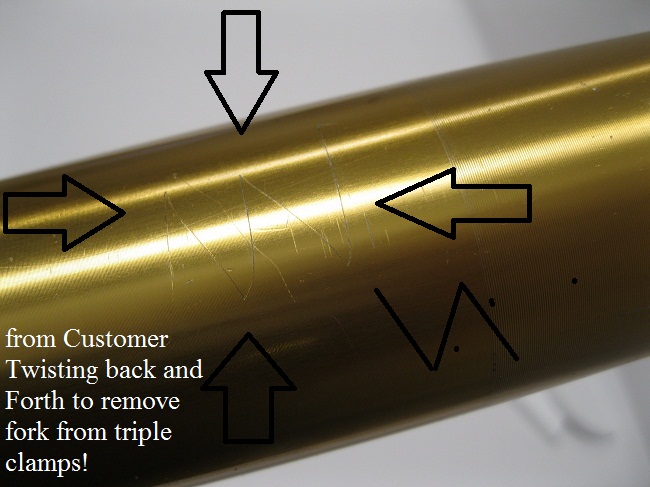

The “Zig-Zag” Pry-OUT with a sharp flat screw driver opening the triple clamp gap to make slide out or fork (gotta twist these back and forth why opening slot to triple clamps because they won’t slide out easy).

4)

The “Improper Package” (really…)

postal

5)

“The Great Unkown” aka Area 51 (CHANNEL LOCKS or PLUMERS PIPE WRENCH?)

6)

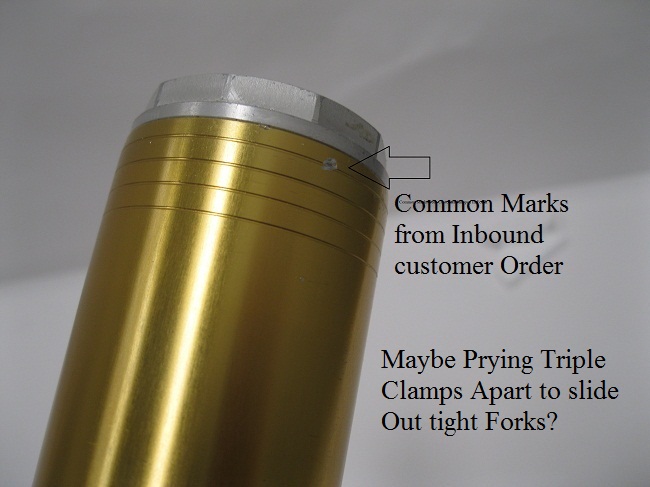

The “Triple Clamp Wood Chisel Spread apart” AKA-“The Chip-Shot” while I slide out my forks from the clamp.

(I really needed three hands so i left a wood chisel or flat screwdriver pounded in the top triple clamp it to wedge apart so i just had to wedge the lower to slide the fork out )

7)

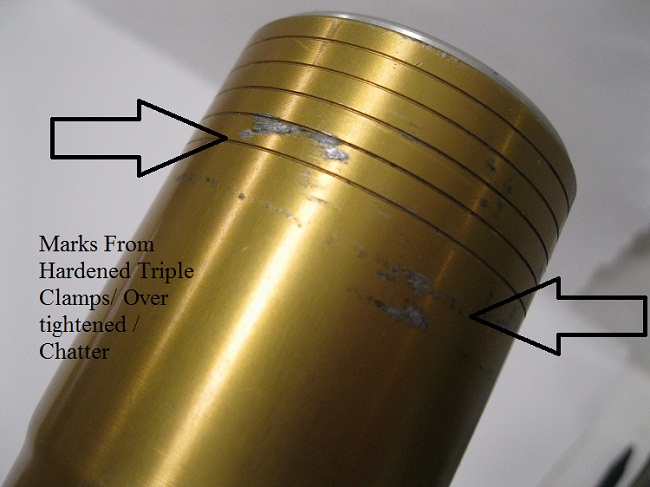

The “Cool Factory Billet Clamps” that are harder than the fork anodizing and chatter even when you torque correctly, more common on bikes with lots of hours.

ABOVE a 2018 Showa “A-Kit” -Whoooooops!

(of coarse not my falt…..) don’t mention the massive bone head move that

“operator error ” caused.

8)

The “Gravel Pit / Sand Pit rider”

(Oh yeah and my old metal tie-down Loop also hits the fork cap sometimes in my pick up truck!)

9)

“WP Anodizing” – Flackey at Best, known to be not so good or durable ).

10)

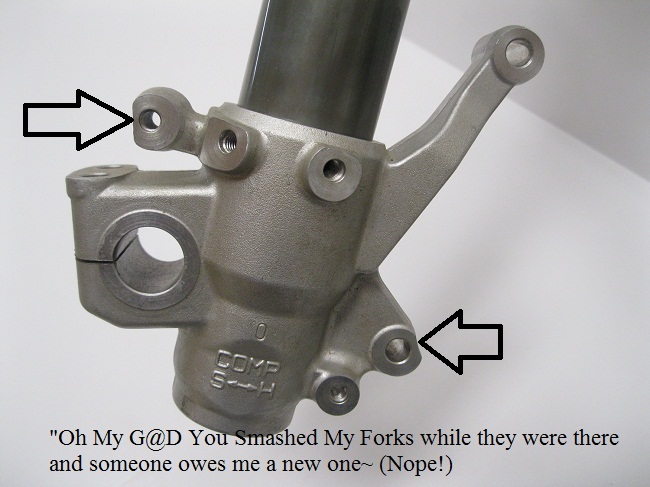

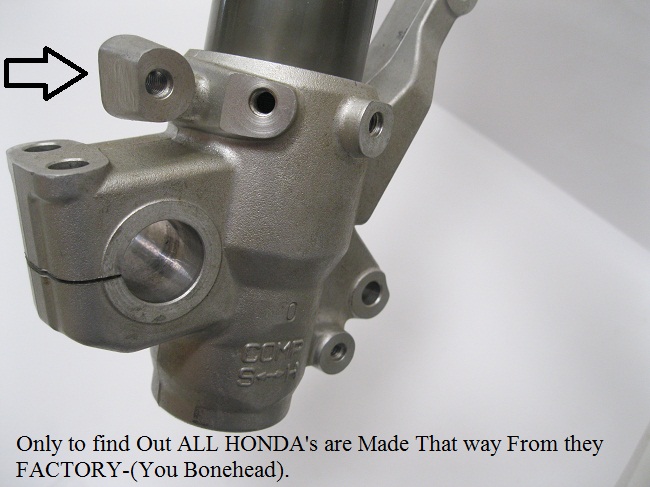

“You Dent Me”~(“really it was not like that before…”).

All the Honda Oem Kayaba /Showa forks were made like this Over 10 years you Bone-Head.

11)

“Oooooooh-” (never mind!).

12)

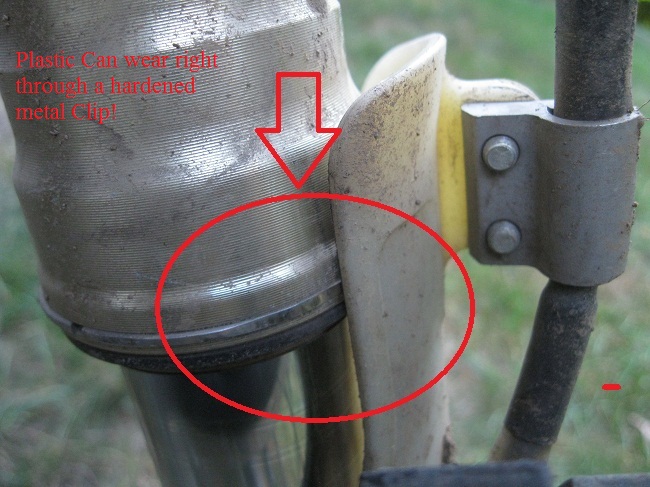

Plastic is harder than metal, guess which wears first.

13)

Common worn clip and thru fork stantion.

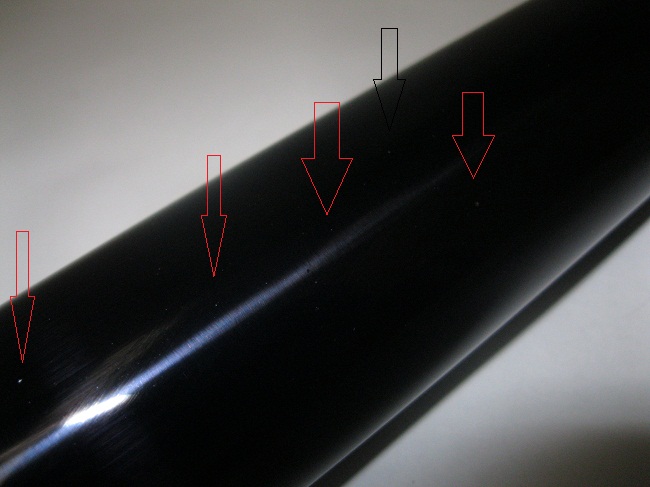

14)

Black anodizing chipped and scratched on stantion tube.

15)

16)

“general Ka-ka”

17)

18)

All carpenters should not try to be small part motorcycle mechanics?

The First Motorcycle was made out of Wood?

19)

Left Dirty in my shed

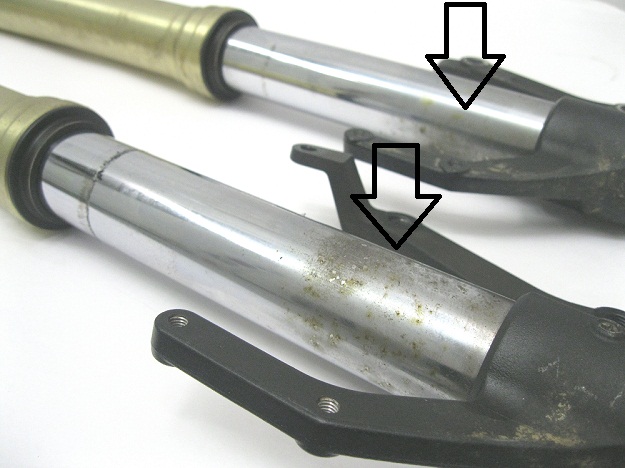

Above black arrows show the pitting on inner tubes, common if your bike left with road dust on the forks too long and exposure.

Above shows cracked rubber wipers seals after only two seasons and many “pits” on chrome tubes that will effect the seal life.

20)

Fox Air shock with pits on canisters that effect seals and air chambers.

21)

Streeky wear marks on chrome tubes may effect seal life, some can be polished out and improved as best as possible without buying new tubes.

22)

The “Zip-Tie” fork tube killer.

A plastic zip-tie on any fork can cause your seal to leak and damage the chrome tube, many people use these for checking the amount of travel they use when riding.

23)

I Ride in Shale Rocks.

24)

Where i ride in upstate PA and NY is all shale ROCKS!

25)

Many Many many Hours.

Yes my bushings and Seals are ALL WORN OUT!

26)

You PIT-ME.

27)

28)

The BLACK Spring Preload WASHERS Shown TOP LEFT START to Get Deformed from Being in Wrong Spot From Customer DIY

They Further Get Munched to OBLIVION and turn into Coffee Grind size flakes to find though out fork internals

THESE WERE CAUGHT EARLY, some are not

THE CORRECT AMOUNT AND PLACEMENT OF THESE IS CRITICAL TO WHAT HAPPENS.

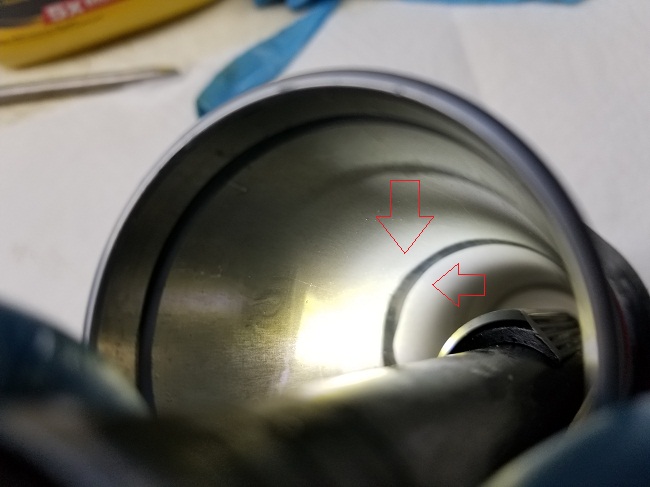

29)

ABOVE RED ARROW,

SOMEONE THOUGHT THE BLACK SPRING PRE-LOAD WASHER SHOULD GO ON THE WRONG SIDE OF THE FORK SPRING, (Whoooops)

30)

Bottom or Top? , Pass or fail?, Doom or Gloom?…. =

CASH or CREDIT CARDS Accepted.

31)

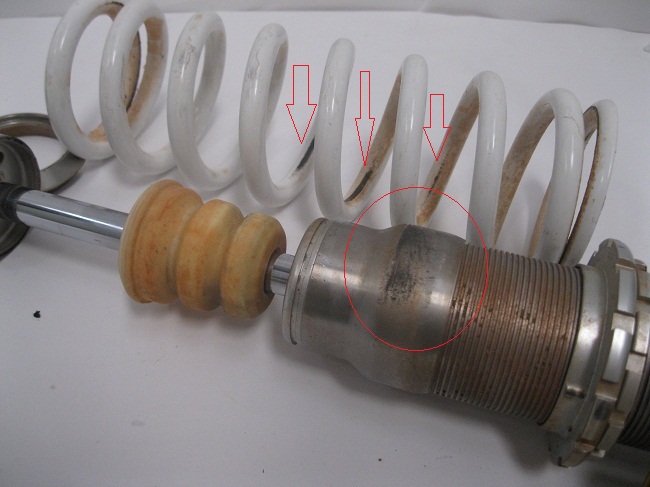

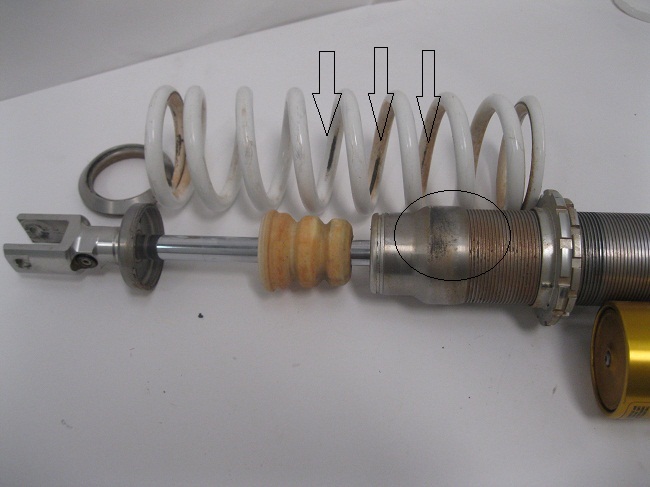

NO Your WP Spring WILL NOT FIT CORRECTLY on an OHLINS SHOCK.

Above if you thought a WP KTM spring would fit on a Ohlins TTX shock it doesn’t.

32)

Above wear marks from wrong fitting spring.

33)

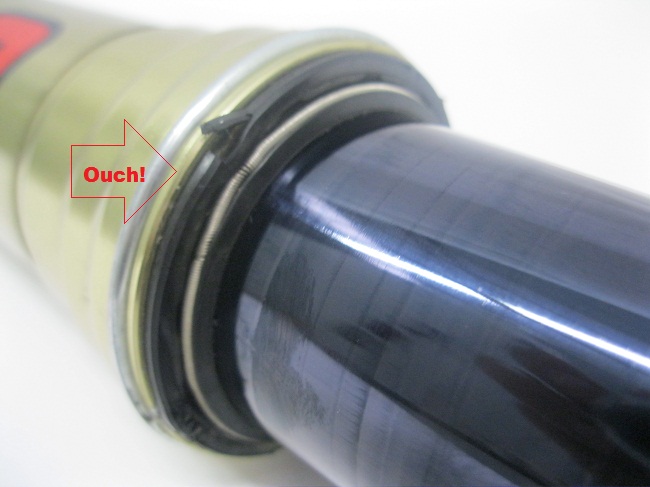

Ouch!

FGHO1596 , from Oklahoma

34)

Mark on DLC coating from wear and tear.

35)

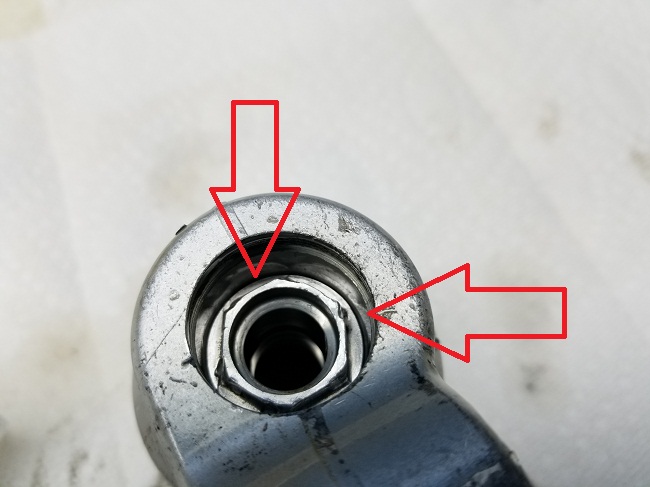

Older 48 RXF fork with varies wear shown.

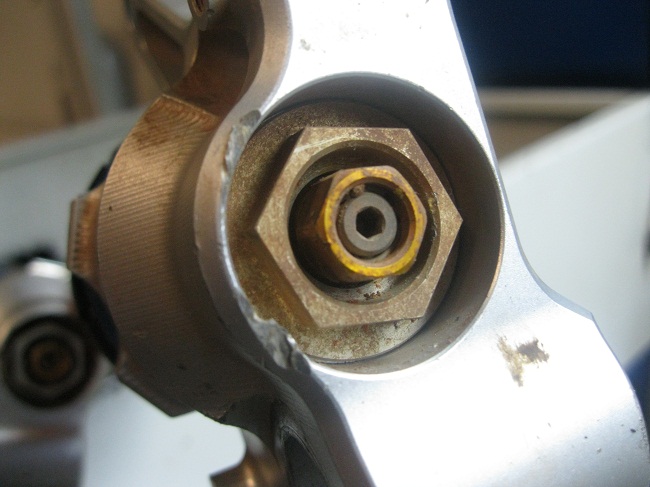

Fork bottoms, reminder the gold nut is “left hand thread” so you can strip them if you did not know this very easy, don’t use crazy air wrenches on these!

36)

Yikes!

37)

Do you really think?

the shocks bottom – Out End Cap needs to be on my Overloaded Adventure Shock Body?

38)

Mushroomed -End -Me .

Body end is Egged out!… end cap just falls off- ridden to death fully overloaded!

“exibit A” and matching end cap”exibit B”

Eeek!

39)

Common DLC COATED fork but closer…

40)

Yikes!…

41)

1983 Husqvarna 250/500 HA5030

42)

“BEFORE”- 1983 Husky HA5030 S36p Vintage Ohlins Pr

43)

“AFTER”

44)

45)

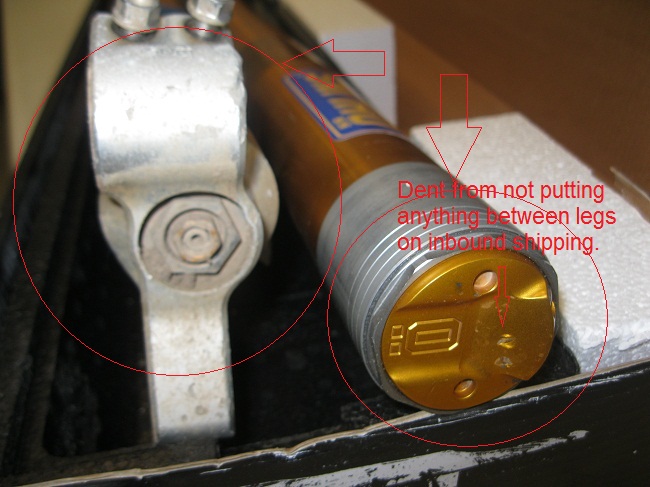

BANG-O ,

maybe put padding or bubble wrap between legs before you ship them in!

46)

Same forks, cap dent , ridden in rock region of USA.

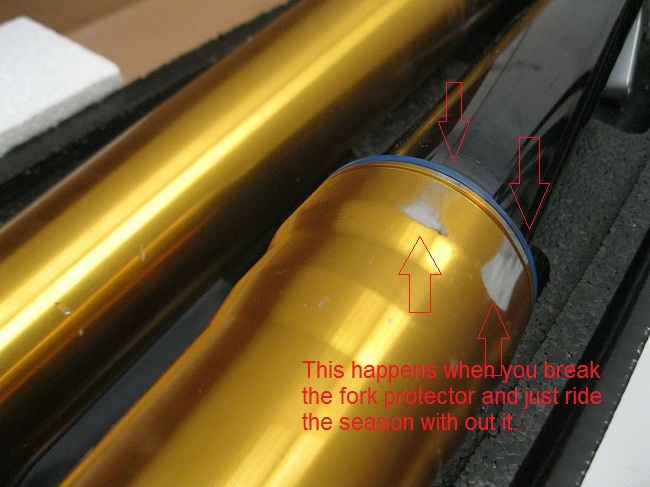

47)

Riding without the $7.50 fork protector guide saves weight?

but cost a New upper gold leg?

48)

49)

Ducati 996S spanners

50)

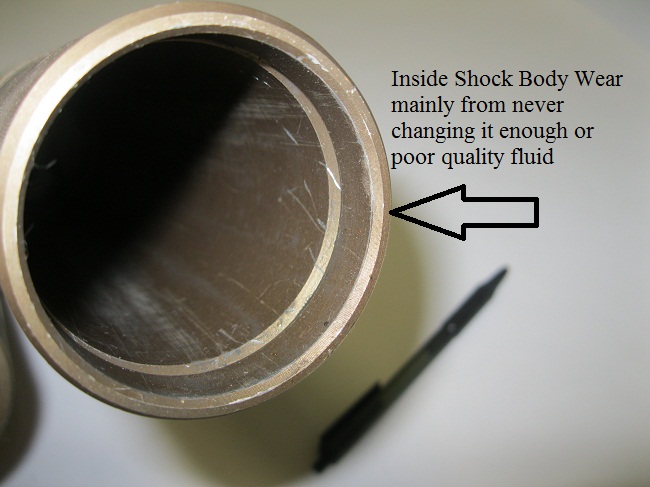

Ducati 996S inner shock body wear.

51)

Origional 2002 Bm215 Bm216

52)

Origional 2002 Bm 215/Bm216 vs 2017 Bm215 /Bm216

53)

You Dirty Bird.

Bmw R1150GSA/GS

54)

Small rock and gravel nicks in DLC black coating can make any seals leak, this customer is in the rock region of PA and New York state.

55)

You pit my shaft.

56)

You pit me more.

57)

Above a high end Ohlins TTx series Front and Rear Bm 679 and Bm 678,

The front is fully exposed like most Bmw Adventure series bikes to any coming mud, road dirt and grim, when left on your bike, the next time the shock moves, it can drags through making things leak any time.

Some go many many years without issues , some go only one season or less depending on your cleanliness and riding habits and bike storage.

58)

Above Vintage Mx Bucket of junk from a Husky on ebay…

59)

Above full restoration Maico 1981 490c

Made like New shocks all new parts except rare Vintage web heads that are NLA.

60)

61)

62)

Honda CRF250L Spring leg Colorado 2018

63)

Vintage Mx Husky on CR125 Honda

64)

65)

66)

67)

68)

Fox Mud-bird

69)

Fox Shaft Rust under bumper

70)

Fox Shaft Mark and ding under bumper

71)

Fox Body wear from Dual Rate springs and plastic spacer rub.

72)

Fox body wear from plastic spring guides.

73)

From others received for check up.

74)

WP Body worn thru massive wear mark and blacked oil extra fast.

75)

WP Body wear 2018 KTM 250Xc

76)

ID Code

77)

From others Spring Preload spacers put in wrong place.

78)

From others No safety clips by others.

79)

From others adapters stripped from others.

80)

From others, one thing or another loose left tube gets walloped, above is right side also seal needs rehab or replacement legs.

81)

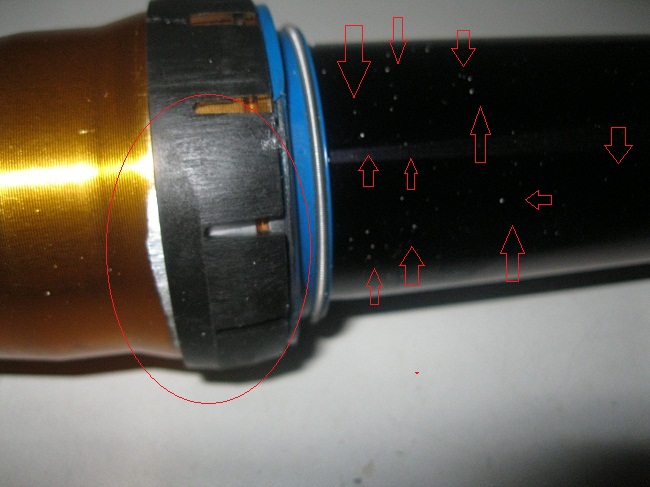

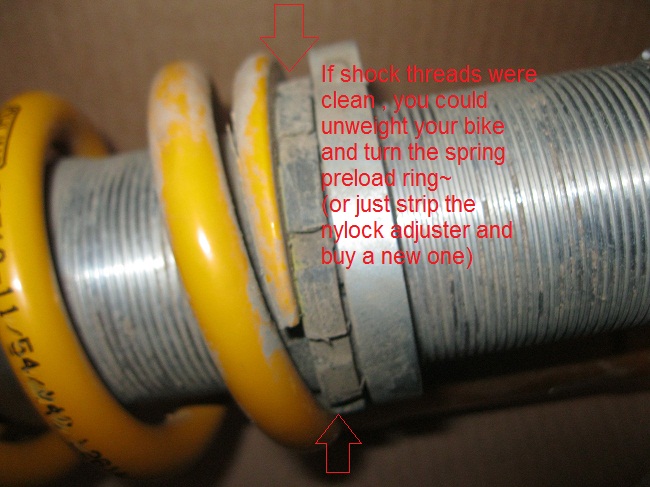

NICE!- Less than 12 months! ECEA Enduro guy loves to use a Brick and Chizel to change his shock spring preload (2019 Husqvarna or KTM found Feb 10 2020)

82)

Same ECEA Enduro guy loves PA ROCKS and Mountains to Flop around on and slide down in the rain!

83)

Same Enduro shock body Threads Semi killed from above hammer/ chezel spring settting,

He also was using an old Yellow CR/CRF Honda Showa spring on this Ohlins shock

Reminder:

(all Yellow spings that don’t say Ohlins, are not Ohlins springs and do not Have same INSIDE or End Dimensions needed to miss the shock body and threads)