Tech-Tools-Pics

DON’T LET YOUR Ohlins Or ANY other Suspension FALL INTO THE WRONG HANDS!

TECH-TOOLS-PICs

1) Rule #1 ,

maybe leave it to the professionals.

2)

3)

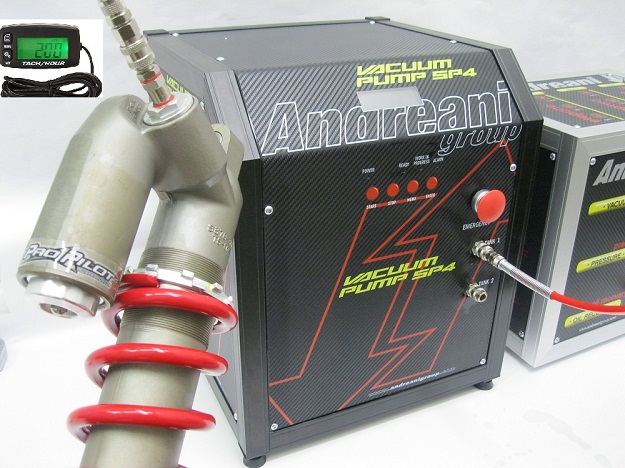

Many years of research and found for many reasons these newest machines are the best of the best.

Andreani Machines are an absolute must for proper suspension, to utilize these to their fullest, it’s the only way to go.

There are super cool (and expensive) adapters and fixtures for every type and brand of Shock, Cartridge and Steering Dampers, allow about 10k to set up both types with base adapters for most components.

Built in San Marino Italy, right down the road from Ferarri, to USA voltage motors so no converters or inverters are needed, just use a Dell computer hook up and cable and your ready to go.

4)

Recycling 100% , upgrade to the best Odorless fluids, they are fully automated and at the push of a button you can have crystal clear fluid down to the Micron, you never need to see that monthly service guy.

5)

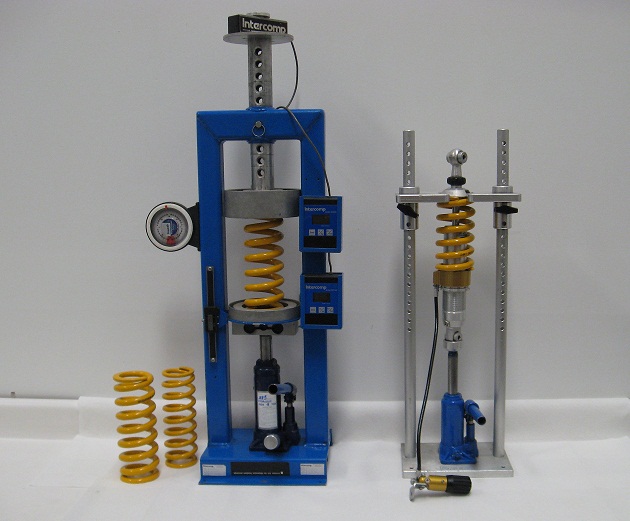

Spring Press Machines that have exact aluminum fixtures to suit most brands to change springs,

A must for any “Remote Hydraulic Preloader” Style Shocks,

Also no need to touch spanners on spanner style shocks, or reset spring preload.

6)

Newest generation Spring Rating and Testing equipment.

The Load Cells should be calibrated occasionally and provide great incite into calculating correct spring values.

Springs should be tested in a more climate controlled room, not extreme cold or variations.

The better 5000lb load cell machines with Fork Spring adapters kits with optional roll stands and spring tools as well as provide product seminars on how to calculate spring force through the entire stroke of a shock shaft travel as well as peak values to compare what the OEM claimed a rate to be.

7)

FORK Spring Upgrade Kit for the above Spring Tester

8)

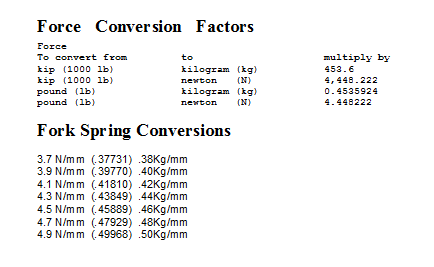

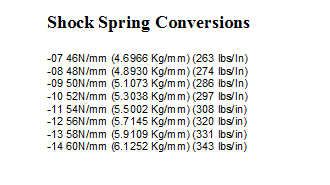

Surprisingly even major suspension companies and publications not informing their customers about the difference between N/mm and Kg/mm.

They are Not the Same Thing!

So when talking about springs it’s best to clarify that.

An Infinite amount of variables may determine a spring choice,bike geometry, engine placement, fork technology, etc.

Many Modern Forks with a .52N/m may Feel Plusher than a Fork with a .48kg,

(don’t be too stuck on just because you used a .43kg in the mid 90’s your current machine needs that number)

Its getting popular to also field check Front rider sag also, it’s a lot harder to do than the rear but possible to do the front Spring preload /Spring rate calculation.

To be most accurate you would need to minimize seal / bushing stiction, fork angle, and other possible alignment issues.

9)

SKF Newest low friction Triple Lip seals and Wear parts

This SKF material has many advantages over traditional designs,

they are also offered in a PSF ‘HD” for the newest generation of Air Forks.

10)

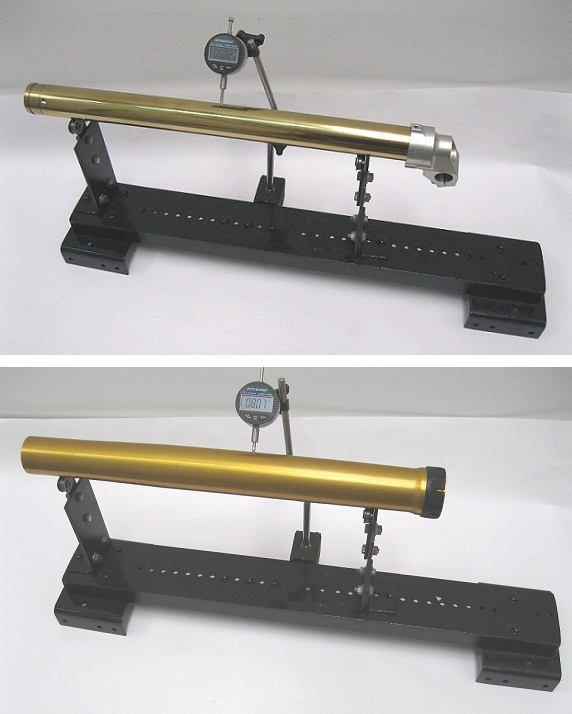

Fork Digital Truing Stand (Check Inner & Outer Legs separately for straightness)

Adjustable with Gauge Magnetic Indicator and Dual Edge Roller Bearings.

Check All tubes to make sure they are straight and not bowed is a must

Before Installing Any New Seals and bushings to make sure they are within manufacturers specs.

11)

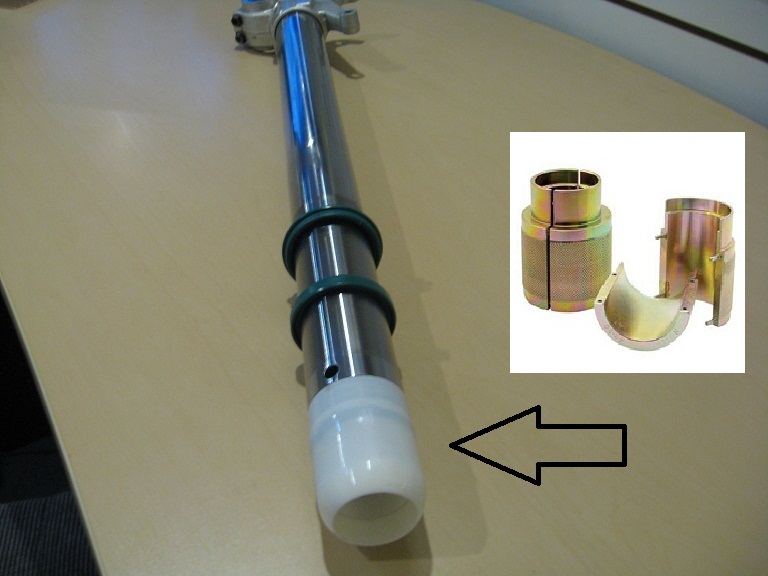

This White Seal and Bushing Install bullet is a Must, We sell various ones (from 36mm-49mm)

Sometimes you can use a heat gun and even make them better,

For a whats hard to see but an almost SEAMLESS TRANSITION to install Seals without damage,

12)

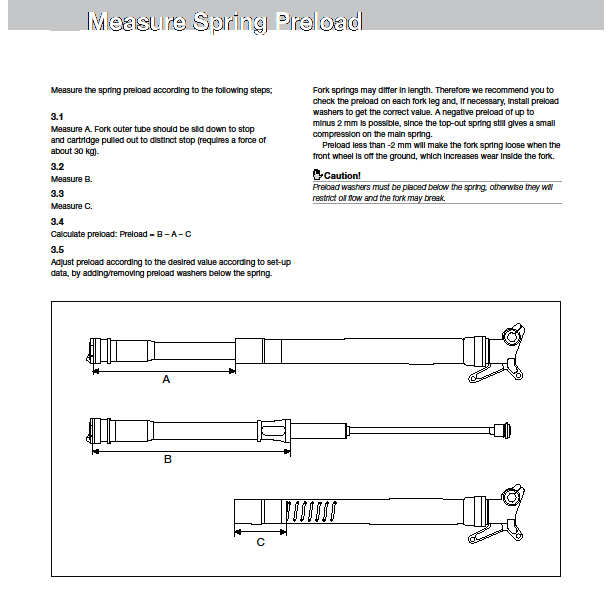

Next thing about Springs to be more in the ballpark (D.I.Y.) info.

(Some Shock Spring A,B,C’s)

You can exactly measure the Free Length of spring (as shown above) usually in mm, while off shock, then installed on shock which is slightly compressed (example maybe 11mm to 16mm depending on what its going on).

Then once all back together field check with some pretty exact measurements .

The fully extended measurement on an arch as axle would travel (record in mm.), then fully settle (meaning you and your stuff two feet up on pegs ) record in mm. “Shazame” that’s called rider sag, adjust that to be within manufacturers spec (measure again and record in mm. within the acceptable range) , then after in range check static sag (that’s bike only no rider) to see what you have left (record in mm.)

All of those above things are then considered to see if a Spring RATE change may be helpful.

They are only as accurate as your measuring skills, body placement and free play in shock mount bearings.

Once within manufacturers range, tuner’s often add or take away a little as a half turn at a time more or less slight turns to further benefit their use.

13)

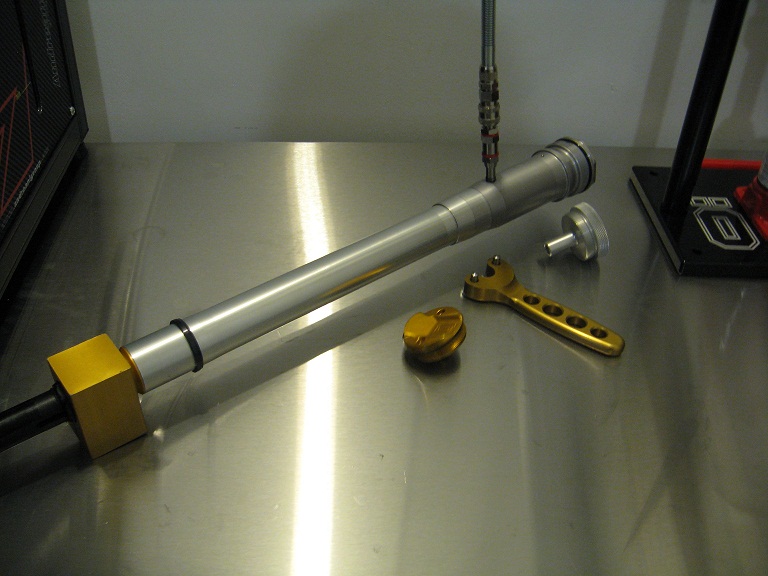

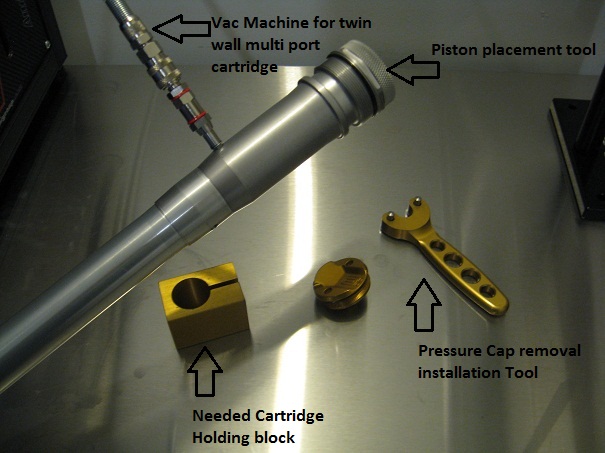

All the new Cartridges need to done on the Vac Machines,way too many places for air to hide, too many little ports, passages, needles, seats and holes by doing them any other way.

These Need to Be done on the Factory vac Machines with the correct fluids and procedures for optimal results.

Ohlins Fluids Must be used in the TTx Struts to Maintain the best ride Quality, without the proper experience and professional procedures, your struts could feel completely different.

14)

Ohlins 4 Litre jug of Suspension Fluid

15)

You need the Piston positioning Tools, cap tools, Holding tools and Factory Andreani Vac machines, and the best quality manufacturers fluids for optimal results.

16)

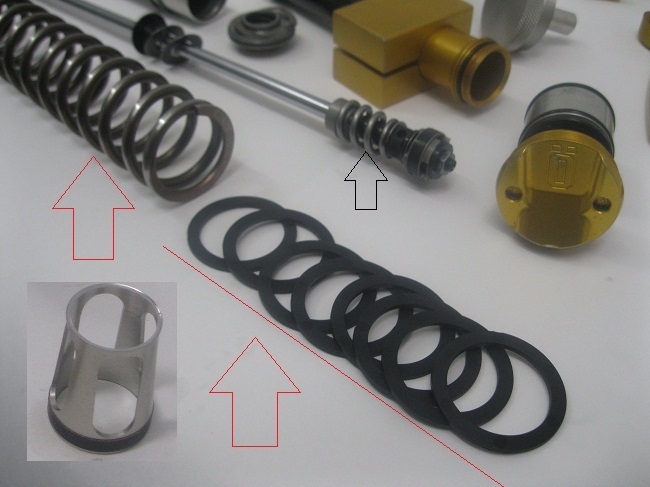

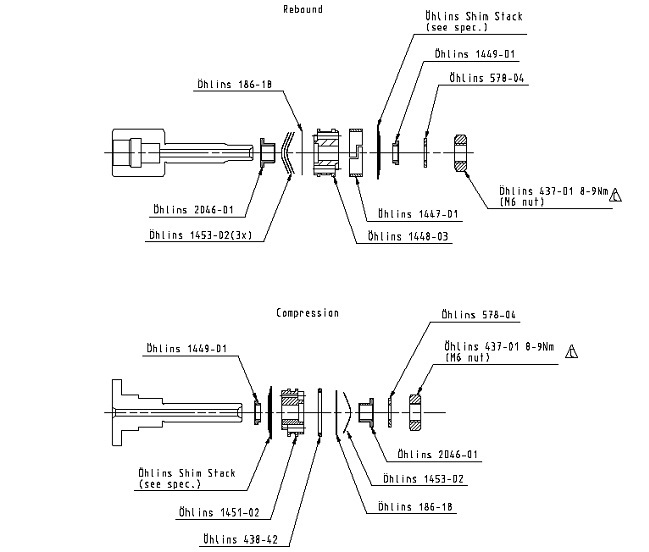

Above, an old dated set of 2009 , lots have been updated since then.

The Red arrows show some important seals and X-Ring bushings wear parts to do at long term rebuild, a million little important passages and places for air to hide so they need to be finished correctly on a professional machine for best results with Ohlins fluid.

17)

Above shows how important the “preload tower washers” from 2x to 11x per leg can be working with the “inner top out spring” for excellent results in forks performance with proper outer fluid volume ranges.

18)

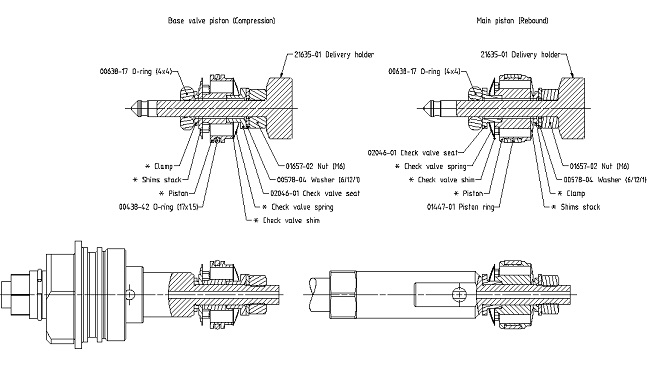

Most Shocks and Cartridges have many passages that can only be done with the Vac machines and the correct tools.

Many have multi piston and Shim designs that also require this procedure, especially Wp, PDS, TTx and most shocks.

20)

Fluid is Very Important , using the Best is like using the best Olive Oil to a master Chef !

Tuners and D.I.Y folks should know every drop counts.

Often times changing fluid volume as little as a couple of tablespoons or even 15cc Per Leg may be a noticeable difference in the air chamber character within the each fork.

Quality additives and ingredients are extremely important to function.

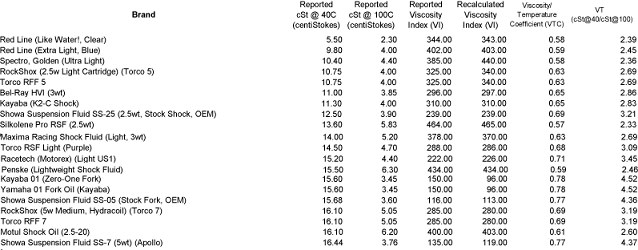

Viscosity index claimed and real index values rated in CSt are often quite unique, a recent study showed some interesting comparison in rating each suspension fluid at what they call 40 degree CSt and 100 degree Cst.

Many brands tested for example called there fluid something like “Very Light” or ‘Light” or a certain ” #5Wt” and tested much higher or lower in reality.

Most modern suspension fluids actual rating is most accurate by referring to the by CSt @40 ‘ or 100′ comparison.

(Here’s just a sample chart of just 20 “Over the Counter Fluids ” of over 150 fluids tested.)

21)

Many variables determine the best ingredients to performance of the suspension fluids.

Viscosity Index

The Viscosity Index is very important in a suspension oil. The viscosity index (V.I.) of an oil is a number that indicates the effect of temperature changes on the viscosity of the oil. A low V.I. signifies a relatively large change of viscosity with changes of temperature. In other words, the oil becomes extremely thin at high temperatures and extremely thick at low temperatures. On the other hand, a high V.I. signifies relatively little change in viscosity over a wide temperature range. So specifically with regard to suspension, the greater the VI, the more consistent the damping will be over a large temp change.

ASTM D2270-04 Standard Practice for Calculating Viscosity Index From Kinematic Viscosity at 40 and 100°C

The Viscosity Index is calculated as such:

On a given morning if the ambient temperature may be 21C (70F) a motorcycle fork may run in the 26C (78F) temp range, rear shocks will run in the 65C (150F) range to even (190F) and the rear reservoirs will be around 43C (110F) to(145F).

While motorcycle rear shocks REQUIRE very HIGH VIs (over 300) to function well over such a huge temperature range, motorcycle forks and bicycles do not. Anything over 100VI will be serviceable for them, however the newest fork designs with internal cartridges are much like rear shock designs so the same fluid is often used in them for best results.

Many variables determine the best ingredients to performance of the suspension fluids.

So just pouring anything into any shock or fork will not provide the intended manufacturers performance.

The ONLY way to professionally get 100% of the air from Shocks and Forks is to use these Machines below

22)

Bulk SPECIAL ORDER very high Quality Valving Shims in various sizes and thicknesses.

23)

These are the University shocks Twin wall TTx Ohlins with both Hi/Lo Rebound and Compression external adjustable, the shock sets have many spring options in 25lb increments.

24)

(Above)This is Ohlins Popular 4 Piston Kit, they are also offered in some application specific kits

25)

26)

27)

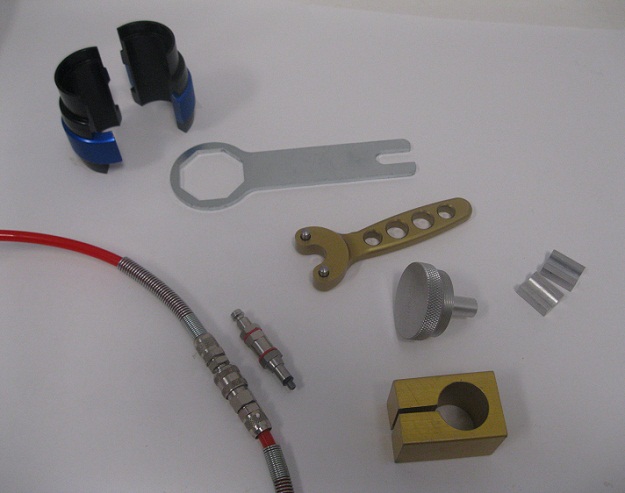

Basic Tool Kit

28)

29)

These are this years Univ. of SoCal’s FSAE Twin Wall TTx Ohlins With both Hi/Lo Adjustable Rebound and Compression, the shocks have spring options in 25lb increments.

30)

Cool Cutaway of a Training Damper so you can see why the correct Vac Machines are the Only way to go.

31)

Air Fork gauge ADAPTER ( a must have to properly check air in forks )

For Example it’s almost impossible to try tuning with manufacturers recommended 6lbs-14lbs increments On The balance and Main chambers with 130psi -145psi in them with a regular pump and gauge.

You loose more or less then that just taking the gauge off and can hear an unknown amount of air escaping.

This simple “T-Style” adapter fits on most pumps and lets you open and close the inner shraeder valve on your forks without air loss like just taking the gauge off does.

The inner “T” pin fully closes or opens the valve before you remove the whole gauge sealing in exactly the pressure you want and has a tunable longer stem to reach.

Even though the above OEM pump/gauges are not that high tech or really accurate, at least you have a much better chance with the adapter.

Below is a Digital Shock Gauge, they are pretty accurate but $469.00!, you can still fill them slowly with your pump (or separate) by attaching to the back and then have the advantage of reading both gauges as accurate cross check.

USE the NEWEST SKF HD Air FORK SEALS !

USE the NEWEST SKF HD Air FORK SEALS !

32)

Air Forks (Love ’em or Hate ’em) but must check the multiple air pressures constantly before every ride!

Tired of checking air all day and never feeling the forks you want? see OHLINS TTx fix Below!

Ohlins TTx Twin wall/Twin piston design

Ohlins TTx Twin wall/Twin piston design

33)

Ohlins TTx Cartridge and Spring Kits (100% reversable /No Machining required)

Above transforms existing AIR FORKS into Ohlins TTx Cartridge and Primary Springs similar to whats in the whole Ohlins TTx 48 RXF Forks.

Many design advantages and unique features ( see more Details and Pic’s around site )

34)

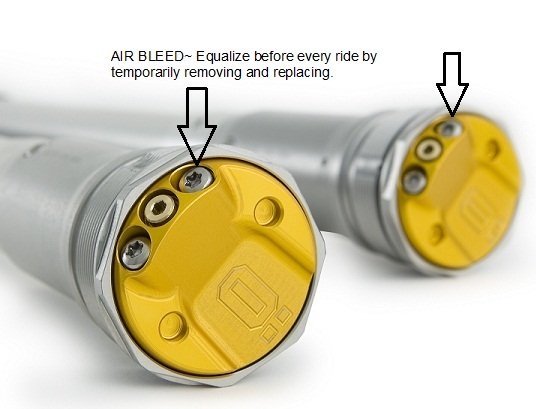

AIR BLEED ~ (shown above)

Before every ride Equalize by removing and replacing the one shown, very similar to any traditional fork for past 30+ years.

REMOTE SPRING PRELOADER’s (101)

Remote spring preloaders ADD some more preload to the preload you already have on the spring, they just do it easier than turning Spanners in a hard to get to space.

For example, your springs Free Length (Off The Shock) may be about 12mm -15mm Longer than installed (On the Shock) length, so you would have 12mm-15mm preload on the spring.

The Remote Preloader when FRESH has a unique Ratio Per application so it may add about 6.5mm-to whatever additional preload on the spring for heavier loading.

Some preloaders can add up to about 15mm more but not as common (and may be a waste?), because the total preload per application and starting preload would be out of range.

The Ohlins traditional preloader (shown below with arrows) will move about that much as shown,

so maybe exposing most all of that hidden spanner under the housing, Some of the other Ohlins Preloaders do more.

35)

The general range of both combined before a spring change may be helpful is about 20mm-23mm total combined.

(So example 14mm preload plus 7mm more=21mm total preload) Some slight variations can apply so not set in stone.

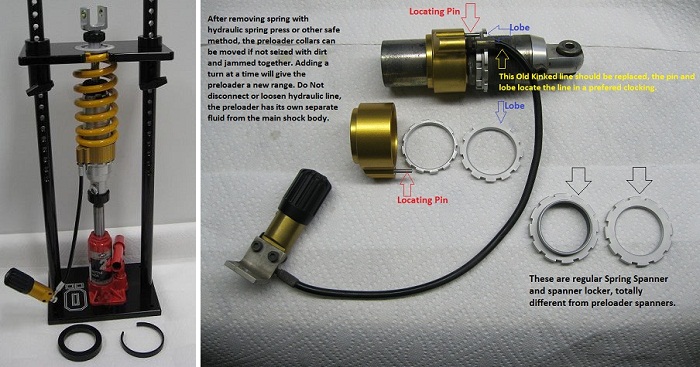

Some folks while the spring is off (Only by using Hydraulic Spring Press Needed) could add a turn to this above double spanner set up so preloader housing would have a new range on the spring to test.(Only if within manufacturers Recommended Specs and Deflection on spring choice)

REBUILDING PRELOADER’S PROPERLY is super detailed and important, they have their own suspension fluid separate from the main shock absorber damper, they need to be done on a VAc machine to 100% for best results and function as shown below.

36)

Once they are Vac machined 100% then they should be load test for full range to manufacturers spec shown below with appropriate fixtures.

37)

Load tested and Maintaining Factory Spec movement then you know that’s how they should be.

38)

39)

Above Left (inny) above Right (outty) , Seal Bullets are a must to do install without possible damage to quad rings.

40)

Penske Shocks & Custom Axis Seals ,Seal heads ,Special Tools

41)

42)

Shown below we have developed specialized adapter kits for most KYB, SHOWA, and other Shocks popular shocks with Bladders and pistons for both forks and shocks!

43)

“No drilling or alterations required” just like the factory meant it to be.

44)

Above, once you remove spring, the older style hydraulic remote preloader has a kinked line that should be replaced, the preloader spanner and lock spanner are totally different size than a regular spring spanner and locker.

The preloader has it’s own fluid separate from the shock, the line should not b e loosened or removed or it would need to be fully rebuilt and purged from air.

Preloader spanners also have a lobe to locate clocking where the line is preferred to locate.

45)

Both gold ones #2 and #3 were a functional hard coat actually done in the same tank but see how different the color varies depending on the minerals like copper in the aluminum casting.

Above, shock bodies used to wear their coatings off back in the day on the inside of the cylinder, a number of body functional hard coats were common.

The fork stantion and leg coatings shown #1 was a light black anodizing type.

46)

Ohlins TTx Mx BAsic CArtridge tool set on some later models, c

47)

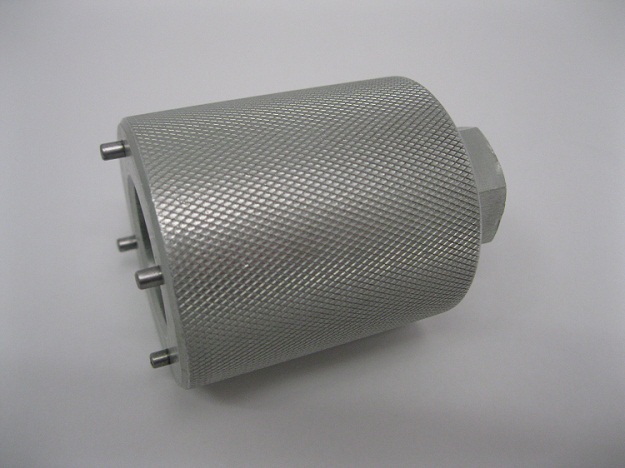

Above Ohlins Road and Track Cap tool popular versions fits many 30mm ,25mm kits and RT Ohlins forks socket and wrench drive.

48)

Above Ohlins Fork numbers identifies what year made and what it is ,Vin number FGKA1896.

49)

Above Ohlins Fork Cartridge number identifies what year made and what it is Vin number.

50)

Above Ohlins TTX Shock number identifies what year made and what it is Vin number KA1894.

51)

Above Ohlins shock numbers identify what year made and what it started out to be, Ohlins CC607-1 .

52)

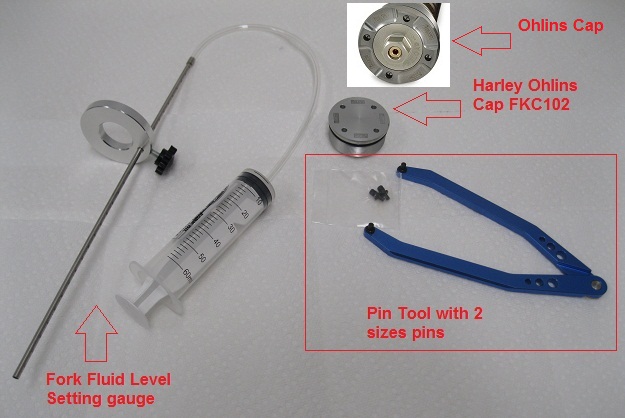

Above Affordable Fork Oil Setting gauge and Universal PIN Tool with extra Pins.

53)

Above SPLIT SEAL DRIVER’s and SEAL INSTALL BULLETS’s available in common sizes: 38mm, 41mm, 43mm, 45mm, 47mm, 48mm, 49mm, 50mm.

54)

Above SKF Seals, Wiper Seals, Stantion Bushings, Inner Leg Bushings Sets.

55)

Above Inner Rebound Rod Holding Tool with Ohlins Fork Fluid Litre (s)

56)

Few years ago now a bone head’s “Squerel-tale” took on a life of its own but was quickly nipped in the Bud, he put the preload washers on top of the spring because easy and he did not use enough for the top out spring-

Make sure the Fork spring preload/shims/washers is in the very bottom of the Ohlins TTX 48 RXF forks as instructions say.

Early on a customer put them near top without enough and had a problem when everything got mashed from his bone head move.

57)

58)

Add Extra fluid in above area to Ohlins 48RXF forks, Not into the air bleeder hole “you-bone-head”.